Legumes – a source of functional proteins

In the search for alternative meal solutions based on proteins from plants, both cereals and legumes have become popular raw materials in recent years. When these are used to supplement or replace meat or fish, they are processed beyond the traditional techniques such as boiling and frying.

Worth knowing

The food industry and consumers want new ingredients with high protein content that once processed provide structure and chewing resistance reminiscent of animal products.

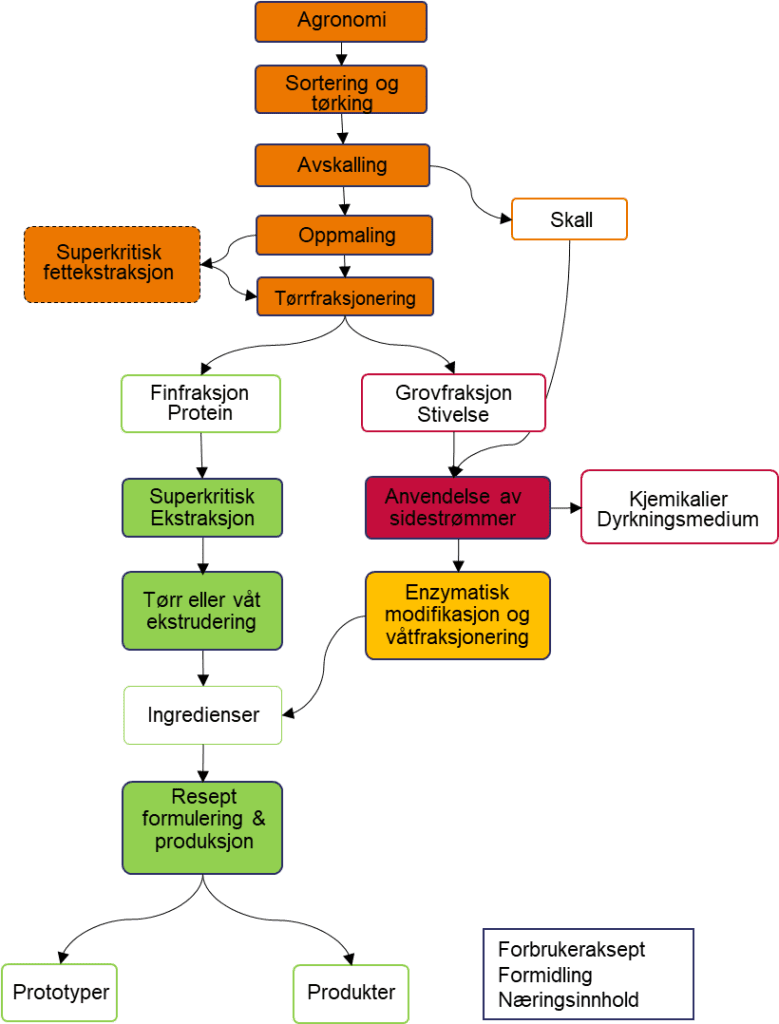

Processing these legumes or cereals involves various processing stages that are governed by the raw materials, ingredients and desired sensory characteristics.

Processing stages relevant when legumes or cereals are to be used for food

The following processing stages are relevant when legumes or cereals are to be used for food:

Dehulling and defatting

After late threshing and cleaning of legumes, the first stage is normally to remove the hull. This is done mechanically by milling or lightly crushing so that the hulls release the kernels and can be blown away using air.

Hulls contain various colour components and structures that are not wanted in the equipment or in the final product. Side streams from this stage might include hulls that can be milled and further processed into fibre with various areas of application.

The principles are also the same for cereals, but defatting is needed before further processing cereals that have a high fat content such as oats.

Supercritical CO2 extraction is a new and resource-efficient defatting process that is being tested on a smaller scale in various research projects. In turn, this process will lead to new ingredients such as oat oil.

Milling and fractionating

Milling processes with the aim of producing a powdered protein involve different milling strategies. Here, the goal is often a protein-rich part and a starch-rich part.

The concentration of protein can take place according to two different processes:

Air classification

Air classification is the easiest way to separate fractions. In this process, the milled powder, or flour, is blown towards a rotating wheel with slits in it so that the coarse fraction, which is mainly starch, is separated from the fine protein fraction.

This process is called dry fractionation. Here, we can increase the protein content in broad bean flour from 30% to 60% and in pea flour from 20% to 45%.

Wet fractionation

Wet fractionation is more energy-intensive, but produces cleaner fractions. In wet fractionation, proteins are dissolved, i.e. extracted, under alkaline conditions and then precipitated again by adjusting the pH.

Wet fractionation involves the use of water, common industrial chemicals such as salts, acids and alkali, and the need to remove water afterwards.

Wet fractionation can concentrate the protein content of pea and broad bean fractions to at least 80%.

Extrusion

The next stage is to make ingredients or a finished product. This is done by forming the protein flour into the desired texture in an extruder.

There are many customisation options in the extrusion process; apparatus settings, temperature, pressure and throughput time are selected based on the desired structure.

If this process takes place with a high water content, we can produce structures similar to meat products. If we use less water, drier pellet-like structures are formed.

A mix of different protein ingredients makes it possible to guide the taste and texture towards a ready-to-cook product, such as an ingredient in burgers or sausages or as a consistency provider in products such as pâtés.

In addition to optimised products in relation to consumer preferences, it is desirable that new processed plant-based food products provide an increased feeling of satiety.

Production pilots in Ås

Complete pilot equipment for dry fractionation has been installed at Nofima. This equipment enables Nofima to study the characteristics of different types of raw material and optimise the separation parameters.

Large-scale systems for dry fractionation have been installed in commercial mills in Stavanger (AM Nutrition and Vestkorn). Large-scale production using wet fractionation has not yet been established in Europe, but suitable pilot plant facilities are available at NMBU.

New opportunities for the food industry

The possibilities for completely new plant products are many, and new products are continuously being developed.

Both supply and demand are increasing. For example, during the SIAL food fair in Paris in November 2022, the majority of the nominated innovations were plant-based.

Ordinary consumers who want to reduce their meat consumption in line with current nutrition recommendations are the target group along with vegetarians and vegans.

New opportunities for farmers

20 years ago, there was no Norwegian production of ripe peas or broad beans, while in 2022, we produced 16,500 acres of broad beans and peas.

Crop rotation is important and it is recommended to allow six years between each time peas or broad beans are grown in the same field.

Nevertheless, the area of cultivated legumes in Norway can be quadrupled. Here, the incentives should be strengthened so that more cereal producers can try their hand at legumes.

Currently, all production goes to animal feed, but the food industry also wants to see food quality when it comes to legumes.

Watch film

This animated film shows you the equipment you need to make plantbased meat alternatives.

Nofima has the necessary equipment and knowledge.